Perfect Production in 6 Stages

Refining technology is of great importance in refined products. All Sunflower oils or all corn oils can be considered the same. It is quite normal to think in this way. When the purchased products are examined in a more comparative way, it can easily be determined that there are high quality variations even among the products of the same brand purchased today and purchased at another time. It can be evaluated in properties such as color, clarity, product performance and different effects on the body after use. The variability in the quality of the crude sunflower oil is very difficult to maintain the stable quality of the product with 4-step standard refining technologies.

Having high technology in refining affects the final product quality and maintaining this quality 100%.

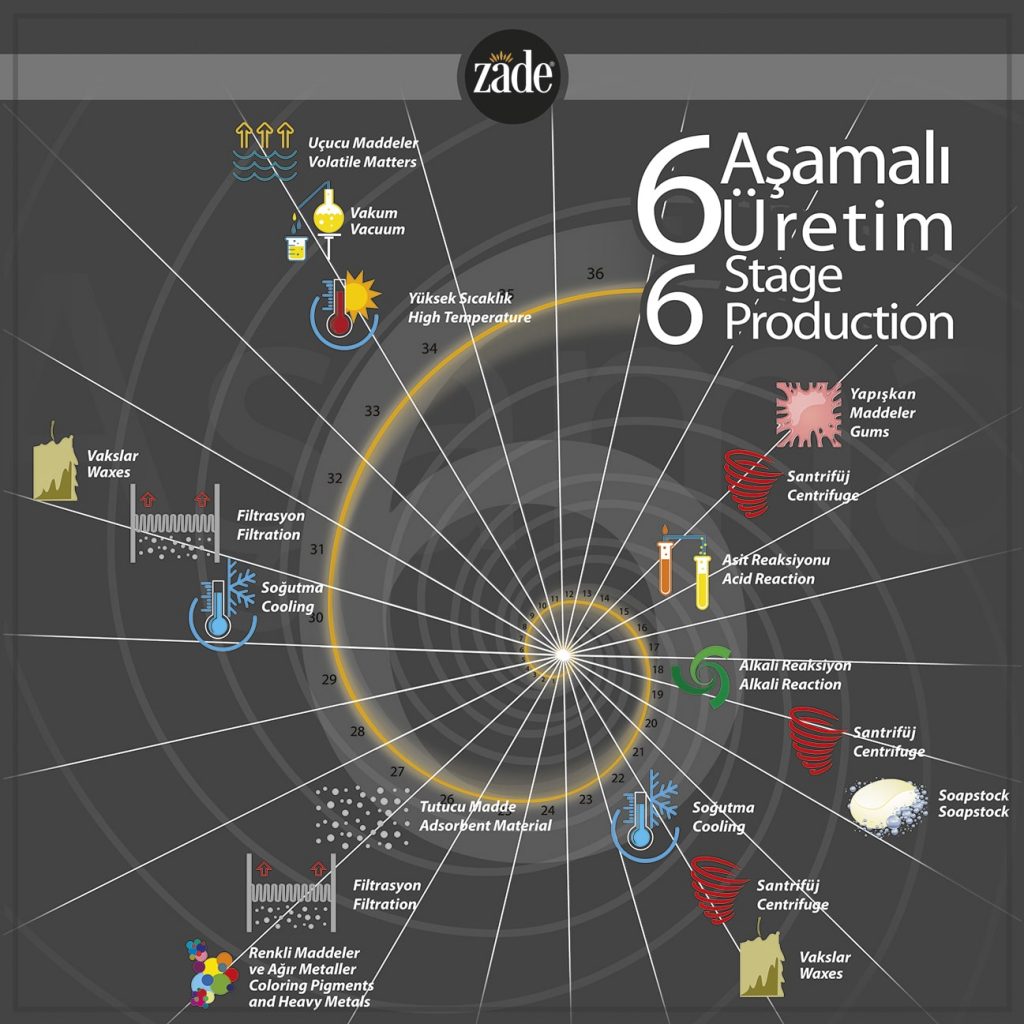

In Zade oil plants, crude oil is accepted if it is compatible with the spectrum determined by the factory. Crude oil goes through 6 different refining stages. With the flexibility of configuring these stages completely separately, the final product standard and quality are maintained. 6 stages configured separately are Degumming (degumming), Dewaxing (wax removal), Notralization (removal of free fatty acids), Bleaching (bleaching), Winterization (crystallization), Deodarization (odor removal) procedures and processes. Oil is a sensitive product, it is important to manufacture in accordance with the nature of the oil. When we want to exemplify sunflower oil; Crude Sunflower oil is refined in 36 hours by processing 6 different stages.

Refining stages and refining time do not vary according to crude oil quality. Thus, each Zade Sunflower oil produced; It is produced by preserving the natural structure of the oil and by removing the negative effects at the maximum level, while at the same time protecting the plant benefits. Thanks to this technology, perfect production is made and this perfect production is maintained in every production. Each bottle of Zade Sunflower oil bought by consumers; It promises the same sensory characteristics and production spectrums specific to Zade determined today and tomorrow.

How to understand and compare the quality of this product? It can be evaluated on sunflower oil.

Every purchased Zade Sunflower Oil can be evaluated visually.. It can be evaluated visually with its clarity, its unique natural color and fluidity.

Performance testing can be done with French fries. Frozen potato can stabilize the potato quality. Zade Sunflower Oil performance results; frying time is shortened and when fried potatoes are placed on a napkin, it is observed that there is no oil in the napkin. These two positive evaluations indicate that the negative effects are taken at the maximum level without deterioriation of the natural structure of the oil.

6 different stages is a production technology, it is the most important part of comprehensive and high technology in Zade Oil Facilities. All kind of vegetable oil production is another different feature of the comprehensive and high-tech Zade Oil facilities which doesnot exist in any other refining plants in Turkey. Sunflower oil, refined olive oil, corn oil, canola oil, peanut oil, grape seed oil, hazelnut oil, safflower oil, soybean oil and much more are produced at the facilities. The number of stages and the time of refining vary in the refining of each plant in accordance with its nature, but not in the product. There is a sensitive production process suitable for the sensitivity of the oil. Every vegetable oil produced in Zade oil plants is produced perfectly in this plant. High quality evaluation can be done visually or after consumption with sensitive stomach.